Need to power something far away or very large? Low voltage might not be enough.

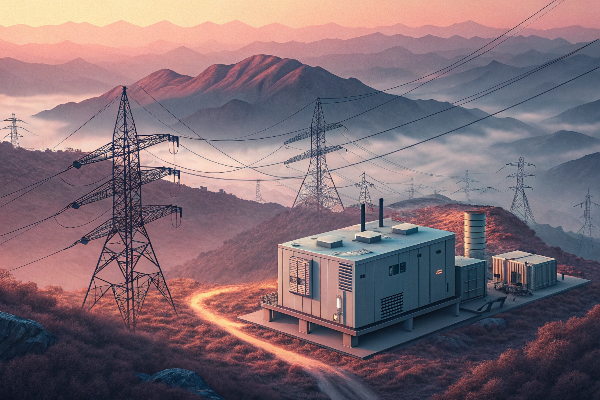

High tension diesel generators1 are used primarily to efficiently transmit large amounts of power over long distances, reducing voltage drop and using smaller cables.

It is about moving power efficiently.

Let us see how.

What are the Primary Advantages of Generating Power at High Voltage Directly?

Why would you make power at high voltage right from the generator?

Generating power at high voltage2 reduces current for a given power level, which minimizes energy loss during transmission and allows for the use of smaller, less expensive cables.

The Benefits of High Voltage Generation

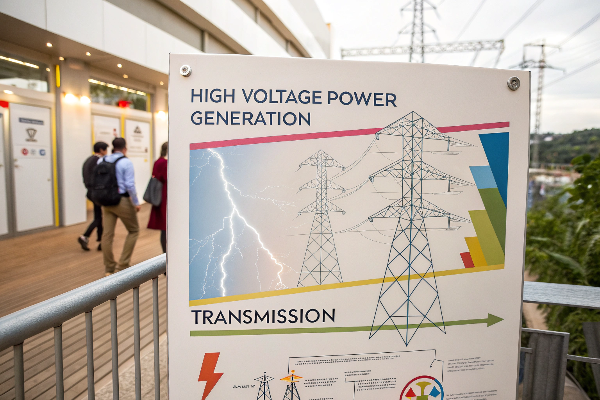

Generating electricity at high voltage (often above 1000 volts) directly from the generator has major benefits, especially when you need to send that power over any significant distance. The basic principle is about power, voltage, and current. Power (P) is Voltage (V) multiplied by Current (I). So, for a fixed amount of power, if you increase the voltage, the current must decrease. Why is lower current good? When electricity flows through a cable, there is resistance. This resistance causes some energy to be lost as heat. The power lost as heat is proportional to the square of the current (Power Loss = Current² * Resistance). This means if you double the current, the power loss increases by four times. But if you double the voltage (and halve the current for the same power), the power loss is reduced to one-quarter.

So, generating at high voltage means lower current for the same amount of power. This lower current means much less energy is wasted as heat in the transmission cables. This saves fuel and makes the system more efficient. For example, sending 1000 kW at 400V requires a very high current. Sending 1000 kW at 11kV requires a much lower current. The power loss in the cable will be significantly less at 11kV. Another big advantage is the cable size. Cables are sized based on the current they need to carry. Lower current means you can use smaller, thinner, and less expensive cables. Using high voltage can save a lot of money on copper cable costs, especially on large projects with long cable runs. It also makes installation easier because smaller cables are lighter and more flexible. For M&E contractors planning power distribution on a large site, the cost and practicality of cable runs are major factors. Using high voltage generation can simplify this greatly. I have seen projects where the cable savings alone justified the decision to go with a high tension generator.

Key Advantages of High Voltage Generation

- Reduced Energy Loss: Lower current means less power lost as heat in cables.

- Improved Efficiency: More power reaches the load, less fuel is wasted.

- Smaller Cable Size: Less current means thinner, lighter, cheaper cables are needed.

- Reduced Voltage Drop: Lower current causes less voltage drop over distance.

-

Cost Savings3: Significant savings on copper cable costs, especially on long runs.

For distribution partners selling generators for industrial projects, understanding the benefits of high voltage generation is important for large clients. Explaining how generating at 6.6kV or 11kV instead of 400V can save them significant money on infrastructure is a strong selling point. For project execution entities, using high voltage generation on a large site simplifies the power distribution network design. Instead of having multiple low-voltage generators spread out or very large low-voltage cables, you can have one or two high-voltage generators feeding substations closer to the loads. My experience with H&C building generators for industrial use confirms that for power outputs above a certain level (often starting around 1MW) or for sites with large footprints, high voltage becomes the more practical and economical choice due to these transmission advantages.Aspect Low Voltage Generation (e.g., 400V) High Voltage Generation (e.g., 11kV) Current (for same Power) High Low Energy Loss in Cables High Low Cable Size Required Large, Heavy, Expensive Smaller, Lighter, Cheaper Voltage Drop More significant over distance Less significant over distance Transmission Distance Limited practicality for long runs Practical for long distances Cable Cost Higher Lower So, generating at high voltage makes it easier and cheaper to send power over distance by reducing waste and cable size.

When is a High Tension Diesel Generator Typically Selected?

In which situations or for what types of projects are high tension generators the better choice?

High tension diesel generators are typically selected for large industrial facilities4, mining operations, construction sites, utility peak shaving5, or any application requiring transmission of significant power over long distances.

Suitable Applications for High Tension Generators

High tension diesel generators are not for every application. For homes or small businesses with loads close to the generator, low voltage is perfectly fine. High tension becomes necessary or advantageous in specific scenarios where large amounts of power need to be moved across a significant area. One common application is large industrial plants or factories. These sites often have many buildings spread out, and the total power requirement is high. Using a high tension generator at a central location and distributing power at high voltage via underground or overhead cables to local substations (which then step down the voltage to usability levels) is much more efficient and cost-effective than running massive low voltage cables everywhere.

Mining operations and large construction sites are other prime examples. These sites can cover huge areas, and power is needed in various locations – for excavators, pumps, processing equipment, site offices, etc. Running low voltage power across kilometers of rugged terrain is impractical due to voltage drop and cable costs. A high tension generator (or generators) can provide a reliable power source that is transmitted at, say, 3.3kV, 6.6kV, or 11kV to different parts of the site, where smaller transformers step it down to the required voltage. Utility peak shaving or standby power for large grids sometimes uses high tension generators. They can connect directly to the medium voltage distribution network without needing a large step-up transformer bank right at the generator terminals (though protection and switching gear are still needed). For our international clients, especially those involved in large infrastructure projects or resource extraction in remote areas, high tension diesel generators6 are often the only viable option for reliable power supply. They are built for the scale and demands of these operations.

Typical High Tension Applications

- Large Factories/Industrial Complexes: Distributing power across a wide area.

- Mining Sites: Powering equipment spread over a large area.

- Large Construction Projects: Providing power to multiple locations on a big site.

- Utility Standby/Peak Shaving: Connecting to the medium voltage grid.

- Remote Power Stations: Generating power for a small town or community far from the main grid.

- Ports and Shipyards: Powering large cranes and facilities.

-

Data Centers (Large Scale): Distributing power to different sections of a large facility.

When a project execution entity is designing the power system for a large industrial project, the choice between low and high voltage generation is one of the first things to consider. It depends on the total power required, the distance over which it needs to be distributed, and the voltages required by the loads. I work with clients to understand their load profile and site layout. If the total load is high (typically above 1 MW) and spread out, a high tension generator usually becomes the more economic and technical choice. For distribution partners selling into these segments, being able to offer high tension units is essential. These are specialized products, and the clients for them have specific, large-scale power needs that low voltage generators cannot meet efficiently. Our H&C units are designed and built with these high-demand, long-distance applications in mind, providing reliable power in voltages up to 13.8kV.Application Scenario Power Requirement Distance Covered Typical Voltage Why High Tension? Large Factory High Moderate to Long MV (e.g., 6.6kV) Efficient distribution across site Mining Operation Very High Long MV/HV (e.g., 11kV) Powering equipment over vast area Large Construction Site High Long MV (e.g., 3.3kV) Distributing power to multiple work zones Utility Grid Connection Very High Short (local) MV Direct connection to network Remote Power Station Moderate to High Long MV Transmitting power to end users So, high tension generators are for projects where lots of power must travel far, like factories, mines, or large construction sites.

How Do Design and Auxiliary Equipment Differ for High Tension vs. Low Voltage Systems?

Are high tension generator systems built differently and need extra equipment compared to low voltage systems?

Yes, high tension generator systems7 require specialized alternators8, more complex switchgear, stricter safety measures, and different cable handling compared to simpler low voltage systems.

Design and Equipment Differences

Designing and installing a high tension diesel generator system is more complex than a low voltage one. The generator itself needs a specialized alternator capable of producing the required high voltage directly. This alternator has different winding insulation and construction to handle the higher voltage stresses. While the diesel engine driving it might be similar to one used for a low voltage generator of the same power, the electrical end is very different. The control system also needs to be designed for high voltage synchronization and protection.

The biggest difference is in the auxiliary equipment, particularly the switchgear. High voltage switchgear is more complex, larger, and more expensive than low voltage switchgear. It includes specialized circuit breakers designed to safely interrupt high voltage currents. Protection relays are more sophisticated to detect faults in the high voltage network. The switchgear might include vacuum or SF6 circuit breakers for reliable operation at high voltages. For safety, high voltage systems require stricter access control, safety interlocks, grounding procedures, and specialized training for personnel. Working on high voltage equipment is much more dangerous than working on low voltage. Cables are also different. High voltage cables have thicker insulation and are handled differently during installation. Terminating high voltage cables requires specialized kits and trained technicians.

Key Design and Equipment Differences

- Alternator: Specialized high voltage windings and insulation needed.

- Switchgear: More complex, larger, more expensive, requires specialized breakers (e.g., vacuum).

- Protection Relays: More sophisticated protection needed for HV network faults.

- Cables: Thicker insulation, different termination procedures, higher cost per meter (but fewer meters needed).

- Safety: Much higher safety standards, strict procedures, specialized training.

- Grounding: More critical and specific grounding requirements.

- Transformers: Step-down transformers are usually needed at the load end.

-

Footprint: HV switchgear often requires more physical space.

For our manufacturing process at H&C, building a high tension generator requires different components for the electrical side and specialized testing procedures. We need to ensure the insulation and switchgear are correctly rated and tested for the specific high voltage the generator will produce (e.g., 3.3kV, 6.6kV, 11kV). For potential customers, understanding these differences means realizing that a high tension system is not just a low voltage system with a bigger engine. It is a fundamentally different electrical design requiring different expertise for installation, operation, and maintenance. For project execution entities, this means budgeting for specialized HV switchgear, cables, and installation labor. For distribution partners, it means needing technical staff with expertise in high voltage systems or partnering with companies that do. My experience is that planning for these differences from the start is crucial for a successful high voltage generator project.System Aspect Low Voltage System High Voltage System Generator Alternator Standard windings, insulation Specialized HV windings, heavy insulation Switchgear Standard breakers, contactors HV Circuit Breakers (Vacuum, SF6), more complex Protection Standard relays Advanced protection relays Cabling Larger conductors needed for high current Smaller conductors possible due to low current Cable Termination Relatively simple Requires specialized kits and training Safety Measures Standard electrical safety Much higher safety standards, strict LOTO Required Expertise Standard electrician HV trained electrical technician/engineer Transformers Step-up needed for transmission (if any) Step-down needed at load points So, high tension systems use specialized parts and need more care during installation and operation because of the higher voltage.

Conclusion

High tension generators efficiently send large power far, used for big sites, needing specialized components and safety.

-

Explore the advantages of high tension diesel generators for efficient power transmission over long distances. ↩

-

Learn how generating power at high voltage reduces energy loss and improves efficiency in power distribution. ↩

-

Discover how high voltage generation can significantly reduce infrastructure costs, especially for large projects. ↩

-

This resource will provide insights into the power needs and infrastructure of large industrial facilities. ↩

-

Learn about the role of high tension generators in utility peak shaving and their impact on energy efficiency. ↩

-

Explore this link to understand the applications and benefits of high tension diesel generators in various industries. ↩

-

Understanding the design differences is crucial for ensuring safety and efficiency in high tension applications. ↩

-

Learning about specialized alternators can help in understanding their role in high voltage applications and their unique requirements. ↩